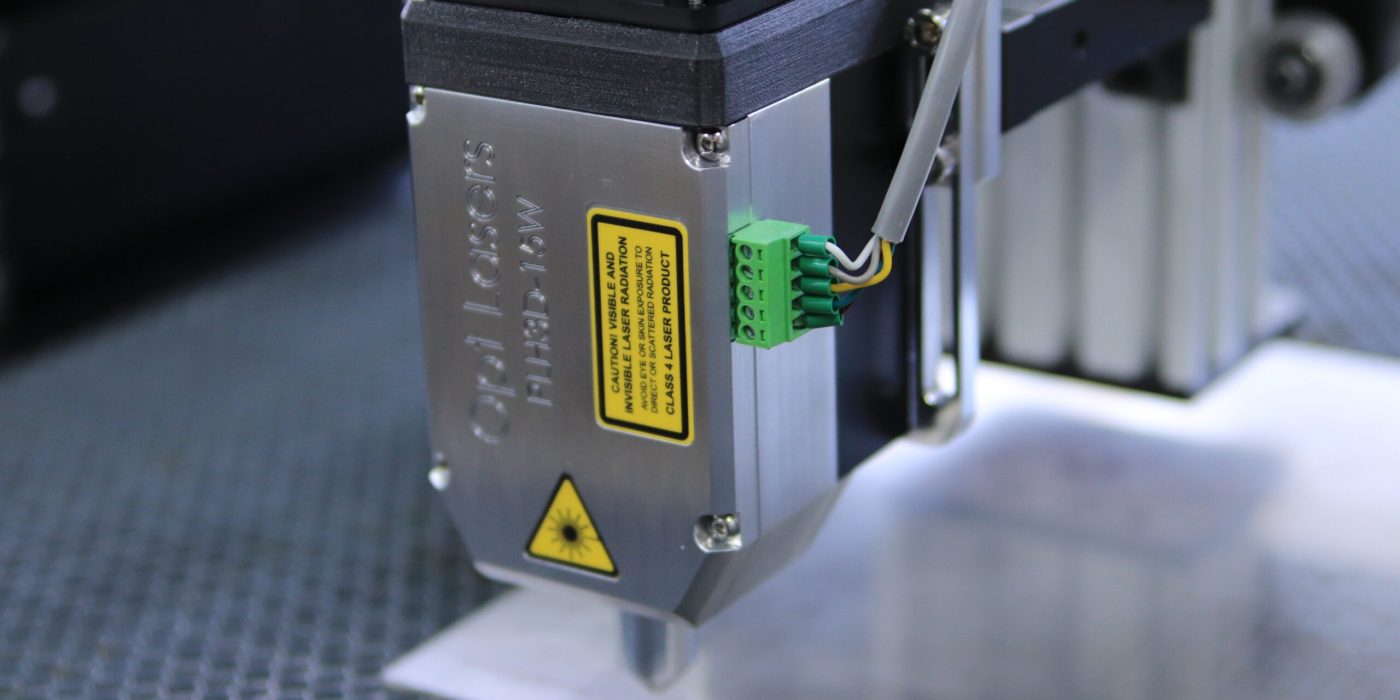

High-quality laser cutting is an exceptional technology for metal fabrication, offering unparalleled precision and efficiency. However, not all metals are created equal when it comes to this cutting-edge technology. This article from Melbourne metal fabricators at BMS Cutting Solutions explores the diverse types of metal that can be successfully utilised in laser cutting processes, shedding light on the characteristics that make each metal suitable for this advanced manufacturing technique.

Ferrous Metals

- Mild Steel

Properties: Mild steel, also known as low carbon steel, is a popular choice for laser cutting due to its affordability and versatility. It is easily cut by the laser beam and produces clean, smooth edges.

Applications: Mild steel is widely used in construction, automotive, and general manufacturing.

- Stainless Steel

Properties: Stainless steel’s corrosion resistance and durability make it a laser-cutting favourite. Its higher carbon content compared to mild steel can result in slightly slower cutting speeds but yields excellent results.

Applications: Stainless steel is prevalent in kitchen appliances, medical instruments, and architectural elements.

- High-Strength Low-Alloy (HSLA) Steel

Properties: HSLA steels offer enhanced strength and toughness without sacrificing formability. Laser cutting is well-suited for these steels, providing precise cuts in various thicknesses.

Applications: HSLA steel is commonly used in structural components, transportation equipment, and heavy machinery.

Non-Ferrous Metals

- Aluminium

Properties: Aluminium’s high reflectivity makes it a bit more challenging to cut with lasers, but modern laser cutting systems equipped with appropriate wavelength adjustments can effectively cut through aluminium sheets.

Applications: Widely used in aerospace, automotive components, and consumer electronics.

- Copper

Properties: Copper’s high thermal conductivity can pose challenges for laser cutting, but advanced laser technologies, such as fibre lasers, have overcome many of these hurdles.

Applications: Copper is utilised in electrical components, plumbing, and artistic applications.

- Brass

Properties: Brass, a copper-zinc alloy, is compatible with laser cutting. It provides an attractive golden appearance and can be intricately cut with a laser beam.

Applications: Commonly found in musical instruments, decorative items, and precision components.

- Titanium

Properties: Known for its strength and low density, titanium can be laser-cut successfully. However, the process requires higher laser power due to titanium’s high melting point.

Applications: Aerospace components, medical implants, and high-performance engineering.

Specialised Metals

- Nickel Alloys

Properties: Alloys such as Inconel and Monel, known for their high-temperature resistance and corrosion resistance, can be laser-cut. However, their toughness may necessitate slower cutting speeds.

Applications: Aerospace, chemical processing, and marine applications.

- Tool Steel

Properties: Tool steel, with its hardness and abrasion resistance, is suitable for laser cutting. However, its high carbon content may result in slightly slower cutting speeds.

Applications: Tool and die manufacturing, injection moulding, and precision machining.

- Alloy Steel

Properties: Alloy steel, with added elements for enhanced strength and durability, can be effectively laser-cut. The specific alloy composition may influence cutting parameters.

Applications: Automotive components, machinery parts, and structural elements.

At BMS Cutting Solutions, we supply high-quality laser cutting services for aluminium, mild steel, and stainless steel.

Considerations for Laser Cutting Different Metals

- Reflectivity: Metals with high reflectivity, such as aluminium and copper, can reflect laser beams, posing challenges during cutting. Advanced laser systems with optimised wavelengths are crucial for successful cutting.

- Thickness: High-quality laser cutting services from BMS Cutting Solutions are versatile and can handle a wide range of metal thicknesses. However, thicker materials may require more laser power and slower cutting speeds.

- Material Composition: Alloying elements and impurities in metals can affect the laser cutting process. Understanding the specific composition of the metal being cut is essential for optimising cutting parameters.

- Speed and Power Settings: Adjusting the laser cutting speed and power settings is crucial for achieving optimal results with different metals. Melbourne metal fabricators fine-tune these parameters ensures clean cuts without compromising material integrity.

Laser cutting offers a multitude of options for manufacturers and fabricators. Each metal type comes with its own set of characteristics, presenting unique challenges and opportunities. As laser cutting technology continues to advance, the range of metals that can be effectively cut expands, opening new possibilities for precision manufacturing across various industries. Understanding the properties and considerations for each metal type empowers Melbourne metal fabricators at BMS Cutting Solutions to harness the full potential of high-quality laser cutting in the pursuit of efficient and exceptional metal fabrication.